We grow through invention and technological innovation

Welcome!

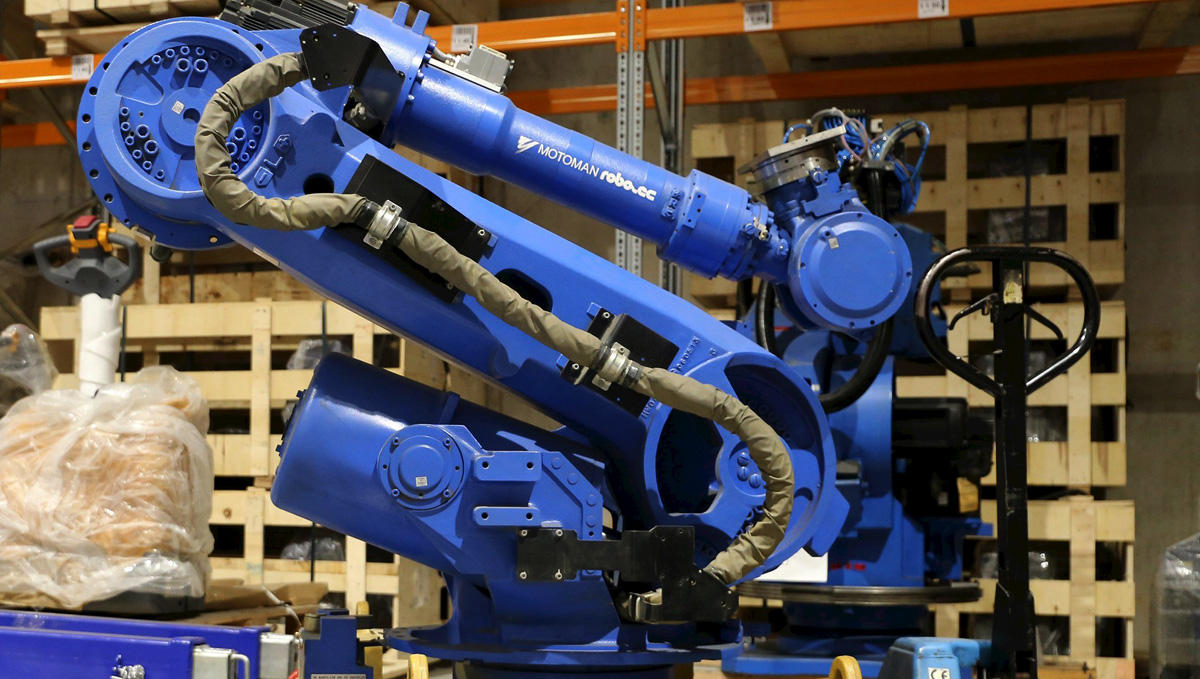

Axis Global Automation Group of Companies is the industry channel partner for Yaskawa Global in India.

Contact

9941 949 555 9841 675 676

Call for free!

Location

#33, Kathir Avenue, Aandal Street, Lakshmipuram, Coimbatore, India.

Core Value

To provide quality services that exceeds our customers expectations.

“Our mission is enable our customers achieve business excellence through automation”

Axis Global

Material handling processes includes all the activities involved in the storage, movement and safety of goods and products in through manufacturing, warehousing and distribution as well as consumption. Typically, material handling accounts for quarter of work force and half of the factory floor space. Almost ninety percent of the production time is spent on material handling processes. Depending on the industry, material handling processes contributes between 15 percent and 70 percent of the cost of the product.

- Reduced Material Handling Costs

- Reduce monotonous and hazardous manual tasks

- Efficient Storage & Distribution of Goods and Products

- Reduction in Material Wastage

- Optimized transfer of materials across the work floor

- Improve Workers safety

Ultimately, material handling systems and processes are established to improve work environment, optimize the supply chain and inventory, shorten the delivery time, improve customer service and reduce overall cost of the handling process. Hence it is necessary to automate the material handling systems using Industrial Robots, Automated Handling Systems and Autonomous Material Transport Systems.

Assisted

Living

Resident

Care

Pharmacy

Support

24/7 Special

Services

Incorporate

Productivity

Robots are faster – By eliminating loading and unloading operations and downtime.

Increase Quality

Robots reduces errors in the process thereby reducing rework and material wastage

ImproveFlexibility

Robots can be used to manufacture different parts without any downtime

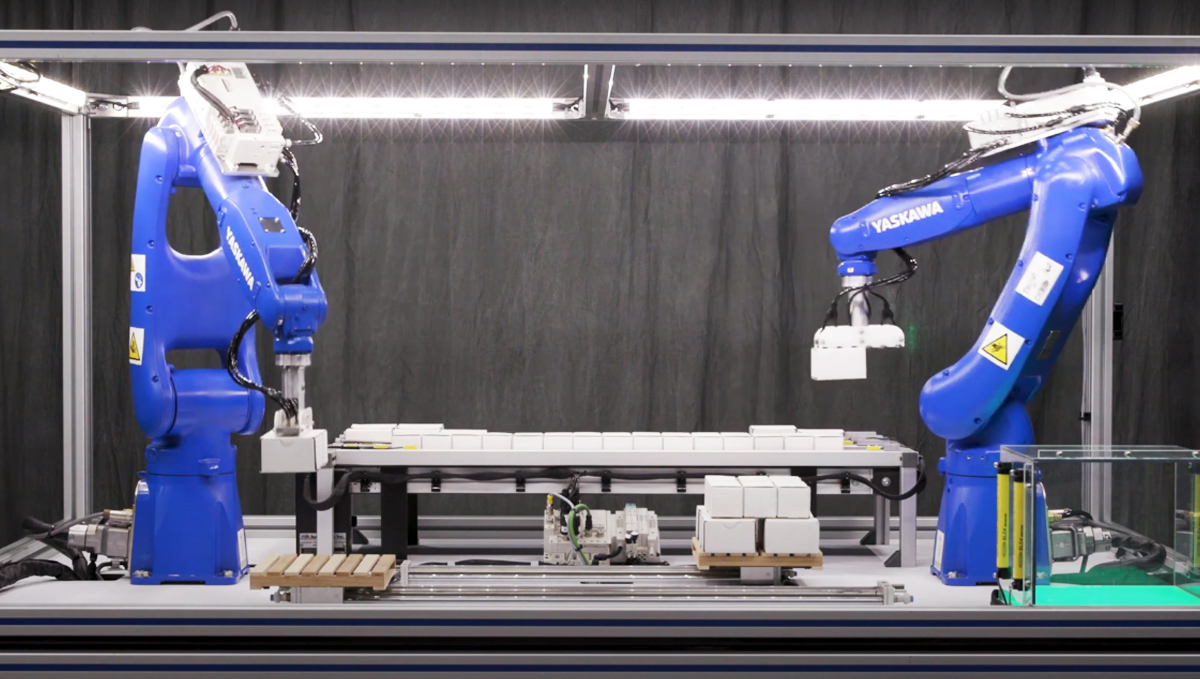

Palletizing Robots perform the act of loading and unloading products into a wooden or plastic pallet for packaging and shipping.

- Safe and accurate palletizing

- Useful for secondary functions

- Enables for flexible palletizing line

- Improved Standardization across the line

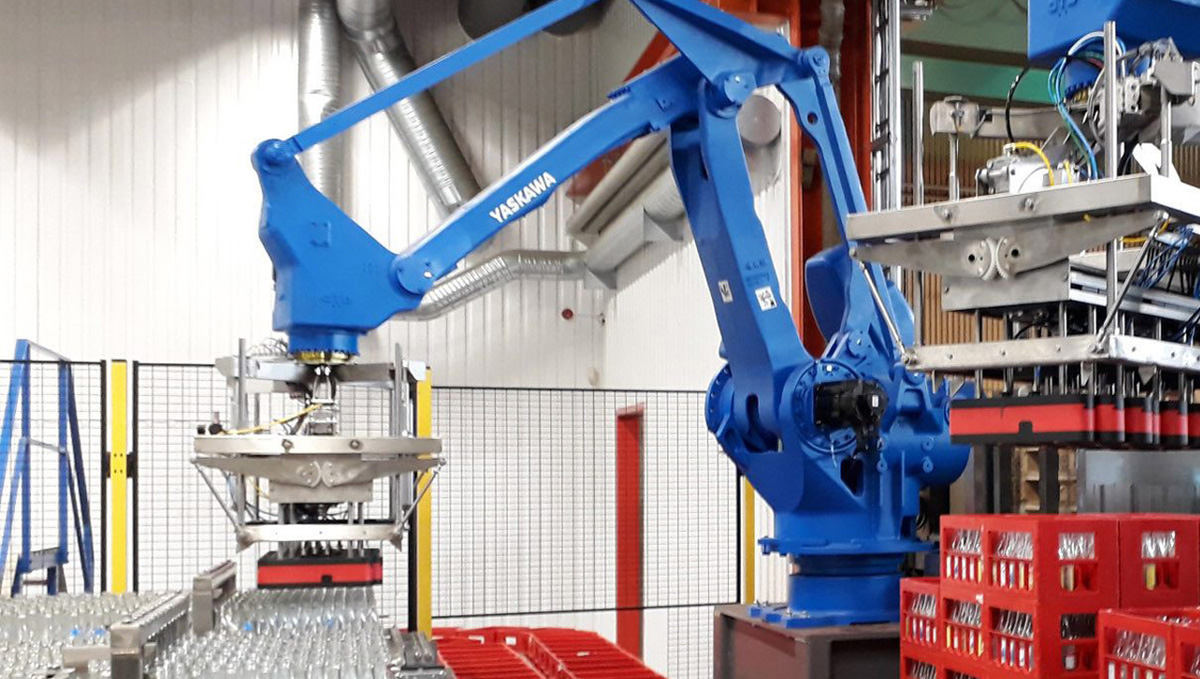

Pick & Place Robots are used to picking up products and placing them onto a determined surface in a pre-set location and orientation.

- Payload capacities from 50 kg to 800 kg.

- Automated pick & place system

- Machine Vision systems

- Material transport equipment

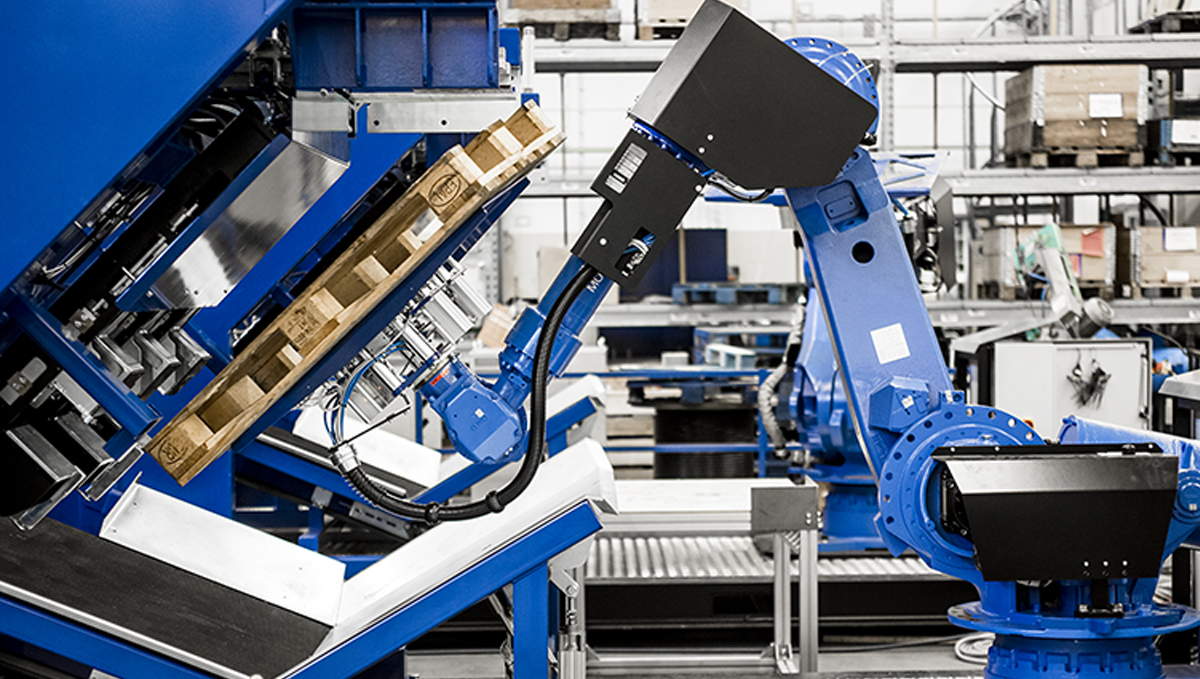

Robotic machine tending systems loading and unloading of parts, products or materials to a machine tool such as CNC, lathes, milling and turning machines, presses etc.

- Compact Solution

- Reduce Machine Overhead Time

- Higher machine utilization capabilities

- Consistent accuracy or tasks

We offer a wide range of industrial robots for performance in harsh environs of casting and foundry industries. The robots are completely sealed & certified with IP67 standard making them waterproof & dust proof.

- Supports wide Payloads from 5 kg to 600 kg

- High Productivity & Throughput of Process

- Low Wastage & Higher Yield

- Safer Work Environment

Industries are increasingly automating their press handling robots to create an ergonomic and safe working environment. It is specifically designed for high performance operations in press shops.

- Heavy-duty drive systems

- Suitable for metal press tending, stamping

- Being used for part transfer, loading & unloading.

- Perform in sorting, picking, placing the product.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad veniam, nostrud mattis luctus.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad veniam, nostrud mattis luctus.

- Palletizing

- Pick & Place

- Machine Tending

- Die Casting & Foundry

- Press Handling

- Description

- Applications

- Benefits

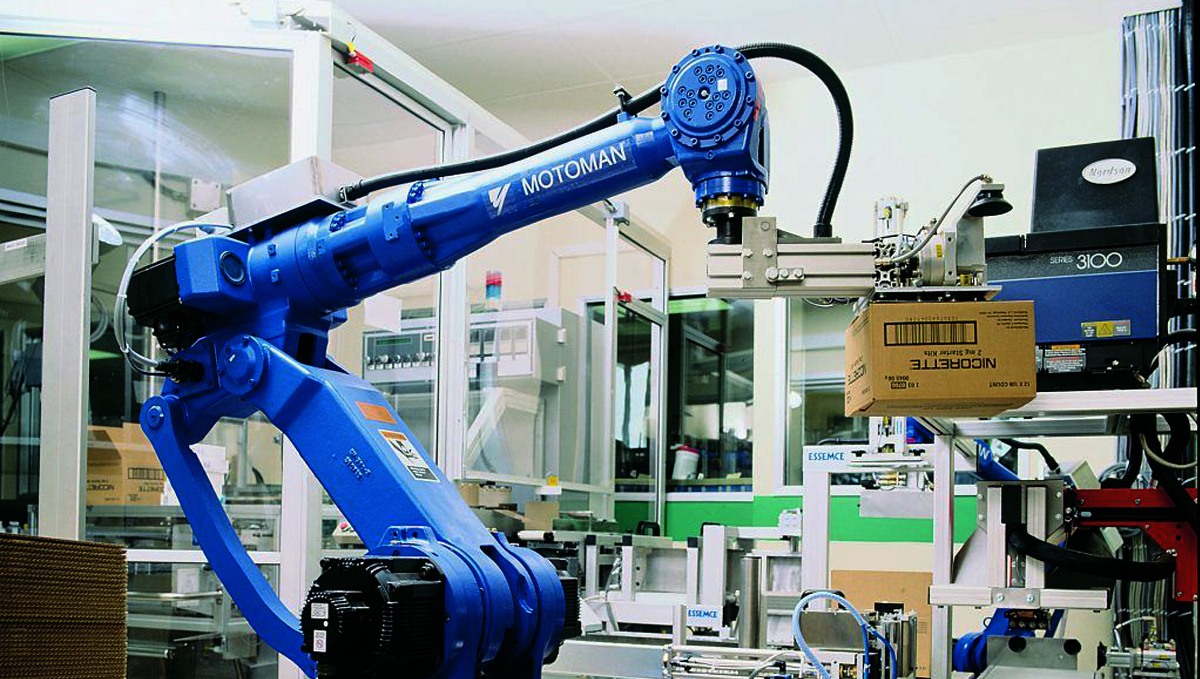

Palletizing Robots perform the act of loading and unloading products into a wooden or plastic pallet for packaging and shipping.

Robots are programmed to collect the products from a conveying system and stack them in the pallets in a pre-determined format. These robots are usually enhanced with pallet dispenser upstream and packaging or wrapping stations downstream to enhance the autonomy of the system and automate the entire palletization process.

Whilst Palletizing is a simpler process, depalletizing requires machine vision systems, dedicated software, and other tools to ensure that the process is completed efficiently.

Palletizing Robots are usually 4,5 or 6-axis robots that automatically loads and unloads goods onto a pallet with a wide range of payloads and work envelopes. In addition to pallets, these robots can also handle tier sheets and slip sheets. We equip the robots with machine vision systems to enable palletizing and depalletizing in all environments.

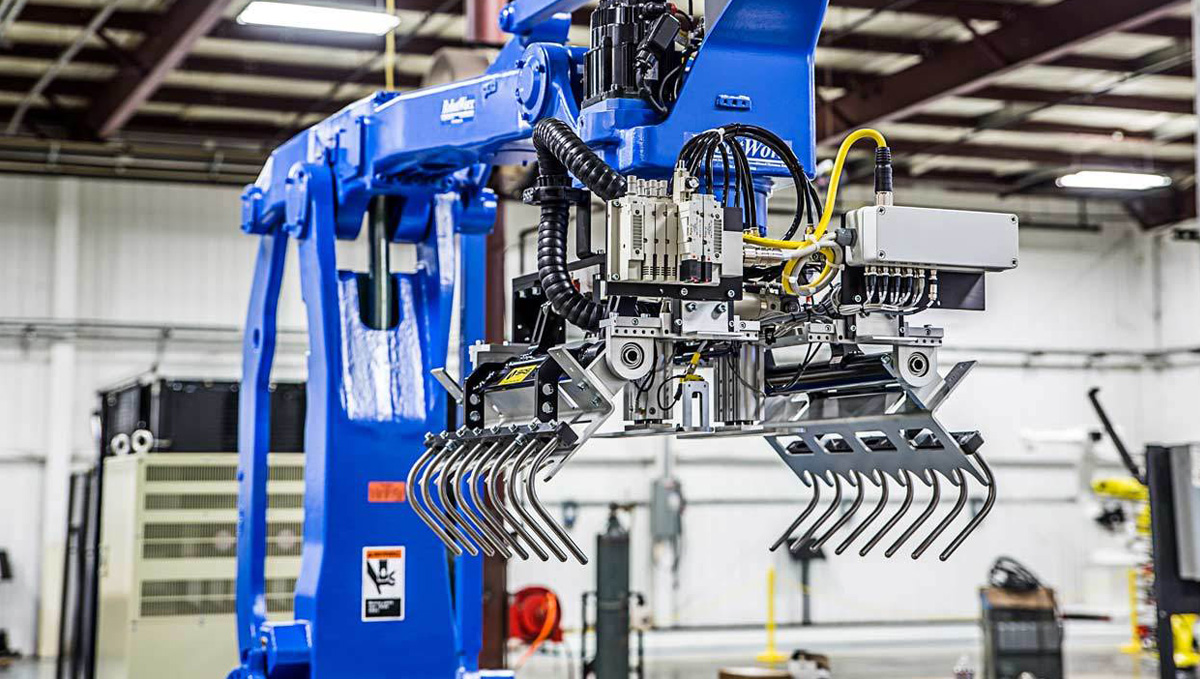

Various gripper styles are available and deployed based on types of palletizing. The following factors are considered when we choose palletizing gripper

- Parallel & Distributed Payload

- High Throughput

- Smooth Handling

Common styles include Bag Gripper, Fingered Gripper, Vacuum Gripper and Magnetic Gripper. We also use customized grippers based on the specific needs of the industry.

- Bag Palletizer

- Case Palletizer

- Mixed Load Palletizer

- Depallatizer

- Secondary Palletizing Functions including Layer and Sheet formation etc.

- Proven palletizing solutions with high reliability and increased throughput, which increases profitability

- Automated Switching of Grippers for different products

- Safe and accurate palletizing

- Useful for secondary functions

- Scalable and Modular Systems which occupies minimal floor space

- Enables for flexible palletizing line

- Improved Standardisation across the line

- Description

- Applications

- Grippers

Pick & Place Robots are used to picking up products and placing them onto a determined surface in a pre-set location and orientation. These robots are commonly used in downstream processes, packing and order fulfilment. Pick & Place Robots can automate repeatitive tasks and perform them faster and with pinpoint accuracy, increased reliability. The robots can be easily programmed and outfitted with tools to handle multiple applications.

Our Pick & Place Robots have a payload between 2kg to 50 kg and offers high speed picking, sorting, and transfer capabilities. They can either have Delta Arms, Articulated Arms and SCARA arms, each offering differing degrees of freedom.

- Assembly Line

- Robot

- Packaging

- Bin Picking

- Inspection

- Pneumatic/Fingered Grippers

- Air Gripper

- Electric Gripper

- Magnetic Gripper

- Vacuum Gripper

- Customized Grippers

We integrate Pick & Place Robots, Machine Vision systems and material transport equipment to create a completely automated pick & place system.

- Description

- Applications

- Benefits

Robotic machine tending systems loading and unloading of parts, products or materials to a machine tool such as CNC, lathes, milling and turning machines, presses etc. Machine Tending Robots allows industries to reduce product life cycle and allows for the process to run continuously thereby offering higher machine utilization and higher throughput. It also eliminates workforce from being engaged in monotonous or hazardous work and allows them to focus on complex tasks.

Machine Tending Robots mimic the role of a human machine operator and often act as an extension of the machine itself. While some robots are simple 1-axis or 2-axis systems, complex machine tending robots have a 7-axis system design, which included 6 industrial robot arms, separate axis for the transportation system (gantry) for consistency and high speed of operations. Payloads vary from 20 kg to 200 kg. Ceiling or overhead mounting is the most common positioning of machine tending robots.

Machine tending can be used for metal working as well as other materials including ceramics, polymers and composites.

Ancillaries including custom grippers, machine vision, barcode verification and labelling units can be added to completely automate the system.

- Grinding

- CNC milling and turning machines

- Injection Mold

- Compression Mold

- Metal Stamping & Forging

- Welding

- Assembly & Testing Machines

- Compact Solution

- Reduce Machine Overhead Time

- Reduces Costs and offers shorter RoI

- Consistent accuracy or tasks

- Reduces human error and Increases quality of operations

- Higher machine utilization capabilities

- Description

- Applications

- Benefits

We offer a wide range of industrial robots for performance in harsh environs of casting and foundry industries. In addition to material handling capabilities, even for ladling molten metal, the robots also perform secondary functions including die lubrication and core making.

The robots are completely sealed and certified with IP67 standard making them waterproof and dust proof. In addition, IP65 certified high-gloss, anti-corrosive bodies ensure that it withstands the caustic elements such as dust, spits and lubricants that are a part of the processes. These robots are built to survive extreme temperatures with high durability.

- Sand Casting

- Chill Casting

- Investment Casting

- Lost foam Casting

- Die Spraying & Lubrication

- Extraction

- Insertion

- Pouring & Ladling

- Molten Metal Ladling

- Cast Cleaning for spruce removal such as trimming

- Machining Processese – Grinding, Milling, Deburring etc.

- Core Assembly

- Dross skimming

- Supports wide Payloads from 5 kg to 600 kg

- High Productivity & Throughput of Process

- Low Wastage

- Higher Yield

- Safer Work Environment

- Robots can be ceiling mounted or wall mounted to save space to achieve optimal product cycle

- Description

- Applications

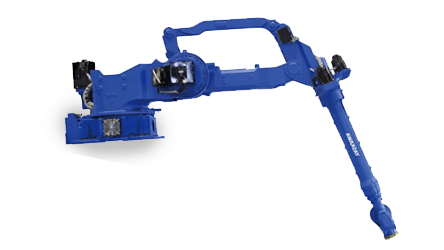

Our Press Handling Range of Robots are specifically designed for high performance operations in press shops. Industries are increasingly automating their press handling processes to create an ergonomic and safe working environment. With long arms, large work envelope and heavy-duty drive systems, the press handling robots are suitable for applications such as metal press tending, stamping as well as secondary functions such as part transfer, loading and unloading. In addition, press handling robots can also perform the activities of sorting, picking, placing, palletizing, polishing, deburring, gauging and inspecting the product.

Our custom end-of-arm tools are suitable for the various press handling needs.

- Metal Press Operation

- Press Tending

- Press Brake

- Packing

Aerospace & Defence

Machinery & Manufacturing

Automotive Ancillary

Commercial / Heavy Vehicles

Agricultural Equipment

Construction Equipments

Food & Beverage

Retail & E-Commerce

Warehousing & Distribution

Water Treatment

Aerospace & Defence

Aerospace & Defence

Aerospace & Defence

Aerospace & Defence

Aerospace & Defence

Aerospace & Defence

Aerospace & Defence

Aerospace & Defence

Aerospace & Defence

Aerospace & Defence

About

Our mission to enable our customers achieve business excellence through automation

Axis Global Automation Group of Companies is one of India’s leading Industrial Automation and Robotics Engineering Solution provider. The company is the industry channel partner for Yaskawa Global (Yaskawa Motoman) in India.

Automation provides an opportunity to enhance the quality, precision, productivity as well as cost-effectiveness of industries. The need of the hour is to choose the right technology that enables the seamless transition of business infrastructure and ensures the achievement of maximum ROI for the technology investment.

Material handling processes includes all the activities involved in the storage, movement and safety of goods and products in through manufacturing, warehousing and distribution as well as consumption. Typically, material handling accounts for quarter of work force and half of the factory floor space. Almost ninety percent of the production time is spent on material handling processes. Depending on the industry, material handling processes contributes between 15 percent and 70 percent of the cost of the product.

Ultimately, material handling systems and processes are established to improve work environment, optimize the supply chain and inventory, shorten the delivery time, improve customer service and reduce overall cost of the handling process. Hence it is necessary to automate the material handling systems using Industrial Robots, Automated Handling Systems and Autonomous Material Transport Systems.

- Reduced Material Handling Costs

- Reduction in Material Wastage

- Reduce monotonous and hazardous manual tasks

- Optimized transfer of materials across the work floor

- Efficient Storage & Distribution of Goods and Products

- Improve Workers safety

- Robots are faster – By eliminating loading and unloading operations and downtime

- In terms of breaks, robots improves productivity and enables better utilization of the

- Equipment investment

- Increased Reliability

- Uninterrupted Change of Manufacturing Processes

- Robots reduces errors in the process thereby reducing rework and material wastage

- Improves Skill Development of Manpower

- By eliminating monotonous and hazardous tasks, it enables employees to upskill themselves in future technologies

- Improves worker job satisfaction

- Improves overall safety of the workforce

- Robots can be used to manufacture different parts without any downtime

- Robots can also be used for secondary processes such as deburring or packaging

- Robots can be easily transported from one location to the other

Our Engineers device a Proof-of-Concept content that encompasses the design, testing and implementation aspects of the system. It enables the end user to visualize the end-result of the project. It also gives an estimate of the feasibility of the solution and also highlights the high-risk areas beforehand.

Our design team develops all the system design and layouts in-house based on the parameters devised in the proof-of-concept phase. Using Softwares such as AutoCAD, Solidworks, Navis , MotoSIM etc. the final system layout and equipment are determined. Special emphasis is given to determine and design the material transport equipment that is ergonomic, efficient, modular, scalable and enables optimization of manpower and work space.

Our Application Engineering integrates a variety of automation technologies to design the best material handling automated system and ensure that the systems work in tandem to achieve maximum productivity. Our process includes

- Build Control Panels in our Panel Manufacturing Unit (located in Coimbatore, India)

- Develop the Control System for the Unit using PLC and integrate the system for better monitoring using HMI screens

- Commissioning and Installation of the System

The electrical hardware systems including electrical components and cable routing as well as the mechanical components such as grippers, pneumatic systems, and other process equipment, are built in-house by our engineers. The safety components are also manufactured in our facility.

The Project Management Team coordinates all the stakeholders including the various team members as well as product supplier and vendors for resource planning to ensure that the project is completed on schedule. Daily tasks scheduling, reviews, approvals, and project completion processes are executed by the project management team.

Our Application Engineers are certified by Yaskawa Japan to conceptualise and execute the best material handling robot suited to the customer’s needs. Our engineers program the robot as per the needs of the job. In addition, they also integrate the control systems with the robot to ensure the seamless performance of the material handling unit.

Once the complete system integration is completed in our facility, it is transported to the customer’s site for final installation and commissioning. Our engineers will handle any troubleshooting needs of the system, if required, in real time. After successful test run and production, the system is handed over to the customer and the project is completed.